Research News

Non-noble Catalyst for Hydrogen Production

Researchers from the University of Tsukuba and collaborating partners have used common metals to produce hydrogen under severe oxidation and at high voltage. This work might lower the cost and increase the sustainability of a future fuel

Tsukuba, Japan—Hydrogen is a promising future fuel—especially if produced from water—but the necessary noble metal catalysts are rare, expensive, and have insufficient reserves. But now, in a study recently published in Advanced Materials, researchers from the University of Tsukuba and collaborating partners have developed catalysts that can overcome the limitations of noble metals.

Hydrogen is a high-energy molecule that can be a renewable future fuel, as burning it only produces water. Unfortunately, most hydrogen is currently sourced from fossil fuel combustion. Hydrogen produced from water would undoubtedly be more environmentally sustainable. However, the metal catalysts required to make this work—such as platinum and iridium—are scarce, costly, and don't perform as well as needed in the harsh and acidic conditions that increase the energy efficiency. Which metal can be an alternative in acidic media instead? Professor Yoshikazu Ito and coworkers' solution is a surprising one: use numerous non-noble metals, all at once.

The researchers used high-entropy alloys, which are mixtures consisting of many elements. Whereas some of these alloys can be used to generate large quantities of hydrogen, others undergo a process called oxidation (i.e., passivation) that imparts some corrosion resistance ability to the alloys. Nevertheless, as Professor Ito points out, "it's apparent that identifying which metals to use in which proportions by conventional bottom-up experiments—i.e., change/add one metal at a time—is quite time-consuming. Our top-down approach not only saves time but also provides invaluable chemical insights into the hydrogen production mechanism."

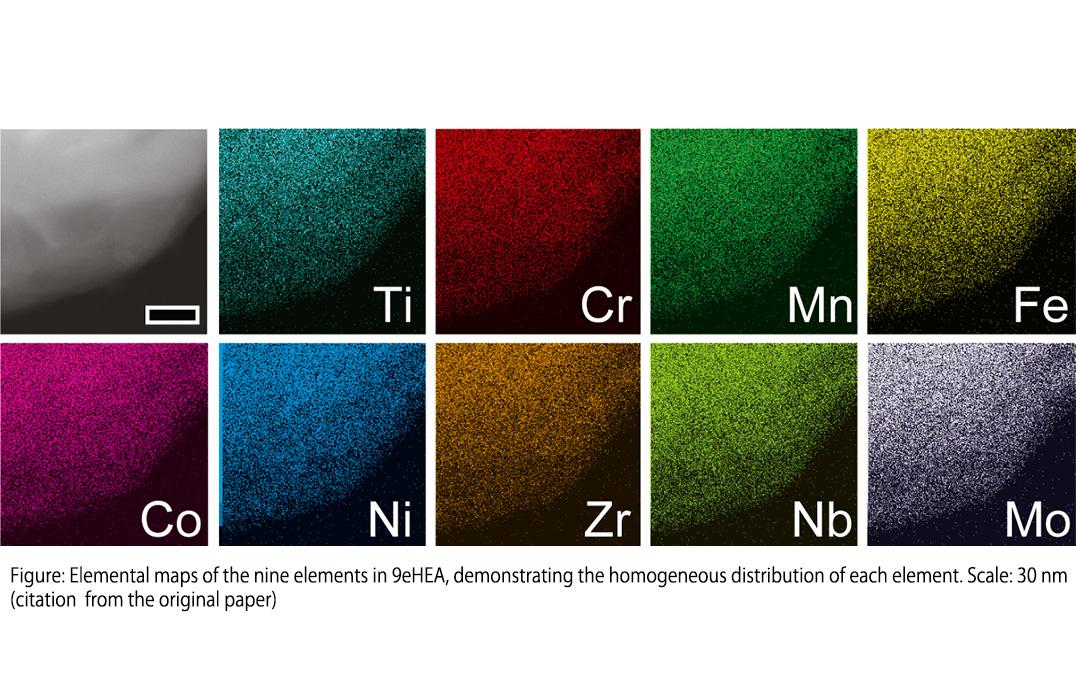

Their approach involves first uniformly mixing the nine elements that constitute the alloy, then passivating the surface in acidic media, and finally applying a voltage to facilitate surface structure rearrangements that optimizes the activity of the catalyst. Experiments and theoretical calculations identified the metals that contributed to catalytic activity (e.g., iron, chromium, nickel, cobalt, and manganese) and the metals that contributed to passivation (e.g., titanium, zirconium, niobium, and molybdenum). The high-entropy alloys' remarkable performance and corrosion resistance were demonstrated in practical water electrolysis experiments. The researchers' study offers novel possibilities and new perspectives toward replacing extremely scarce noble metals, particularly iridium with a worldwide production of only 7 tonnes per year. With a surge in the use of water electrolyzers globally, the demand for iridium is expected to be 700 kilograms per gigawatt.

"In the experimentally challenging conditions of 0.5 molar sulfuric acid electrolyte, it was necessary to sacrifice some stability to maximize the activity, and vice versa," explains Ms. Aimi A. H. Tajuddin (1st author, PhD student). "The catalyst exhibited an overvoltage of only hundreds of millivolts at 10 milliamps per square meter in the hydrogen and oxygen evolution reactions. Furthermore, its remarkable performance remained steady during electrochemical cycling tests, equivalent to 3-4 years of endurance in water electrolyzers operated by intermittent renewable energy sources such as solar power."

This work succeeded in providing a proof-of-concept for a novel, noble-metal-free, economically feasible hydrogen production method from water by using renewable energy. The method costs only a few hundred U.S. dollars per kilogram of catalyst and is suitable for mass-production. The application of high-entropy alloys by the researchers will allow for the production of hydrogen, batteries, and other products that would otherwise require expensive metals.

###

This work was sponsored by the TEPCO Memorial Foundation; JST-PRESTO Grant Number JPMJPR2115; the ENEOS Hydrogen Trust Fund; JSPS Grant-in-Aid for Scientific Research on Innovative Areas "Discrete Geometric Analysis for Materials Design" (Grant Numbers JP20H04628 and JP20H04639) and "High Entropy Submitted to 15 Alloys" (Grant Number JP19H05166 and JP21H00140); JSPS-Kakenhi (Grant Numbers JP21H02037 and JP21H00153); the support of The Research Grant against Global Warming of the Ichimura Foundation for New Technology; NIMS microstructural characterization platform as a program of "Nanotechnology Platform Project," MEXT, Japan (Grant Number: JPMXP09A20NM0013); JACI Prize for Outstanding Achievements; Toyota Riken Scholar; Research Foundation for the Electrotechnology of Chubu; Hitachi Metals-Materials Science Foundation; Kanamori Foundation; the Open Facility, Research Facility Center for Science and Technology, University of Tsukuba; and a cooperative program (Proposal No. 202011- CRKEQ-0001) of the CRDAM-IMR, Tohoku University.

Original Paper

The article, "Corrosion-resistant and high-entropic non-noble-metal electrodes for oxygen evolution in acidic media," was published in Advanced Materials at DOI: 10.1002/adma.202207466

Correspondence

Associate Professor ITO Yoshikazu

Faculty of Pure and Applied Sciences, University of Tsukuba

Related Link

Faculty of Pure and Applied Sciences